Radiofrequency shielding (RF) prevents radiofrequency electromagnetic impulses that create radio frequency interference (RFI). RF shielding involves surrounding possible sources and victims of an electromagnetic field, cable lines, and electronic device circuits with barriers built of conductive and magnetic materials to isolate them from their surroundings. Read More…

PMT shielding solutions is an industry leader in thin film metallic coatings, providing EMI/RFI shielding for advanced technology applications. With years of experience in vacuum metallization, functional finishes, and a commitment to quality and on-time delivery, you can count on PMT to protect the equipment that protects lives.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

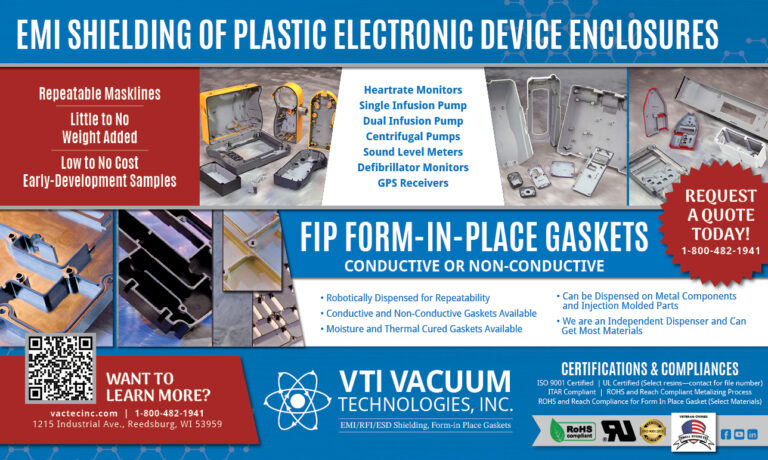

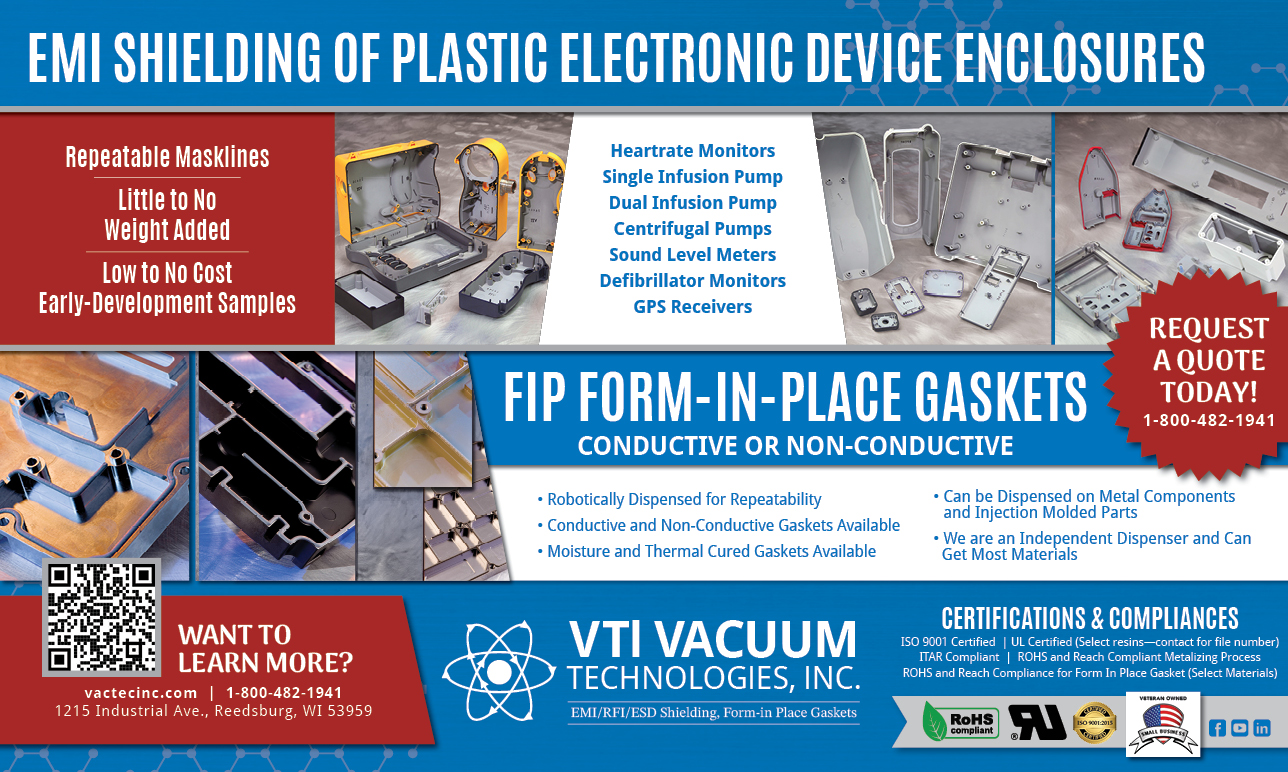

At VTI Vacuum Technologies Inc., we specialize in delivering high-performance EMI shielding solutions that protect sensitive electronics from electromagnetic interference and ensure the reliability of critical systems. As experts in vacuum metallization, we apply precision coatings to plastic enclosures and components, creating conductive barriers that meet or exceed industry shielding...

At V Technical Textiles, we have built our reputation on delivering advanced solutions for electromagnetic interference shielding that protect sensitive equipment and ensure reliability in critical environments. We specialize in designing and manufacturing technical fabrics and materials that meet the demanding requirements of industries where electronic performance, safety, and durability are...

More RF Shielding Companies

Comprehensive Guide to RF Shielding: Materials, Methods, and Supplier Selection

Radio Frequency (RF) interference can significantly impair a device's electrical circuits, disrupting their ability to function normally and potentially causing costly malfunctions or failures. As electronic devices become more prevalent and complex, the risk of electromagnetic interference (EMI) and RF interference (RFI) increases across industries, from consumer electronics to critical medical equipment. Effective RF shielding is a cornerstone of electromagnetic compatibility (EMC) strategies, ensuring device reliability, safety, and regulatory compliance.

Key factors affecting the performance of RF shields include the shielding material’s conductivity, design geometry, thickness, electromagnetic frequency range, and the presence of any gaps or discontinuities in the shield. These elements determine how well a shield can attenuate, reflect, or absorb unwanted electromagnetic signals. Understanding the science and application of RF shielding is critical for engineers, procurement managers, and facility planners alike.

What is RF Shielding and Why is it Important?

RF shielding, also known as electromagnetic shielding, refers to the use of barrier materials or enclosures to block or reduce electromagnetic fields (EMFs) and radiofrequency signals from entering or leaving an electronic device or sensitive area. The purpose is to prevent electromagnetic interference that can degrade the performance of electronic circuits, disrupt data transmission, or even damage sensitive electronic components.

RF interference can affect different devices in various ways. Communication systems, industrial control equipment, wireless networks, and consumer electronics all risk operational issues due to electromagnetic noise. In the real world, electrical circuits can emit as well as be susceptible to RF electromagnetic impulses. Implementing RF shielding protects equipment from these negative effects, helping organizations maintain compliance with government regulations such as FCC, CE, or MIL-STD-461, and ensures the longevity and reliability of electronic products.

RF Shielding Materials: Properties, Applications, and Selection Criteria

The effectiveness of an RF shield depends largely on the choice of material. The ability to reflect, absorb, or block the electrical and magnetic components of electromagnetic waves is determined by a material's conductivity, magnetic permeability, and physical properties. When selecting RF shielding materials, engineers must consider the frequency of interest, shield geometry, thickness, environmental resistance, and cost constraints. Here is an in-depth overview of the most commonly used shielding materials:

Steel

Steel and other ferromagnetic materials are widely used for low-frequency magnetic field shielding. Unlike copper alloys and aluminum, steel offers high magnetic permeability and efficiently directs magnetic flux lines, making it ideal for applications involving low-frequency EMI and RFI. Low-carbon steels possess increased permeability and higher saturation points compared to high-carbon steels, allowing them to withstand stronger magnetic fields without losing effectiveness. Steel shields are commonly found in power transformers, industrial enclosures, and sensitive laboratory environments where low-frequency interference is a concern.

Copper

Copper is regarded as the gold standard for RF shielding due to its exceptional conductivity and ability to attenuate both electric and magnetic components of electromagnetic waves. Copper shields provide broad-spectrum protection across a wide frequency range, from kilohertz (kHz) to gigahertz (GHz). The material’s malleability enables fabrication into custom shapes and enclosures, making it highly adaptable for shielding electronic device housings, cables, and printed circuit boards (PCBs). Additionally, copper is resistant to environmental oxidation and naturally resists corrosion, ensuring long-term durability. Common applications include medical imaging rooms, data centers, and aerospace electronics.

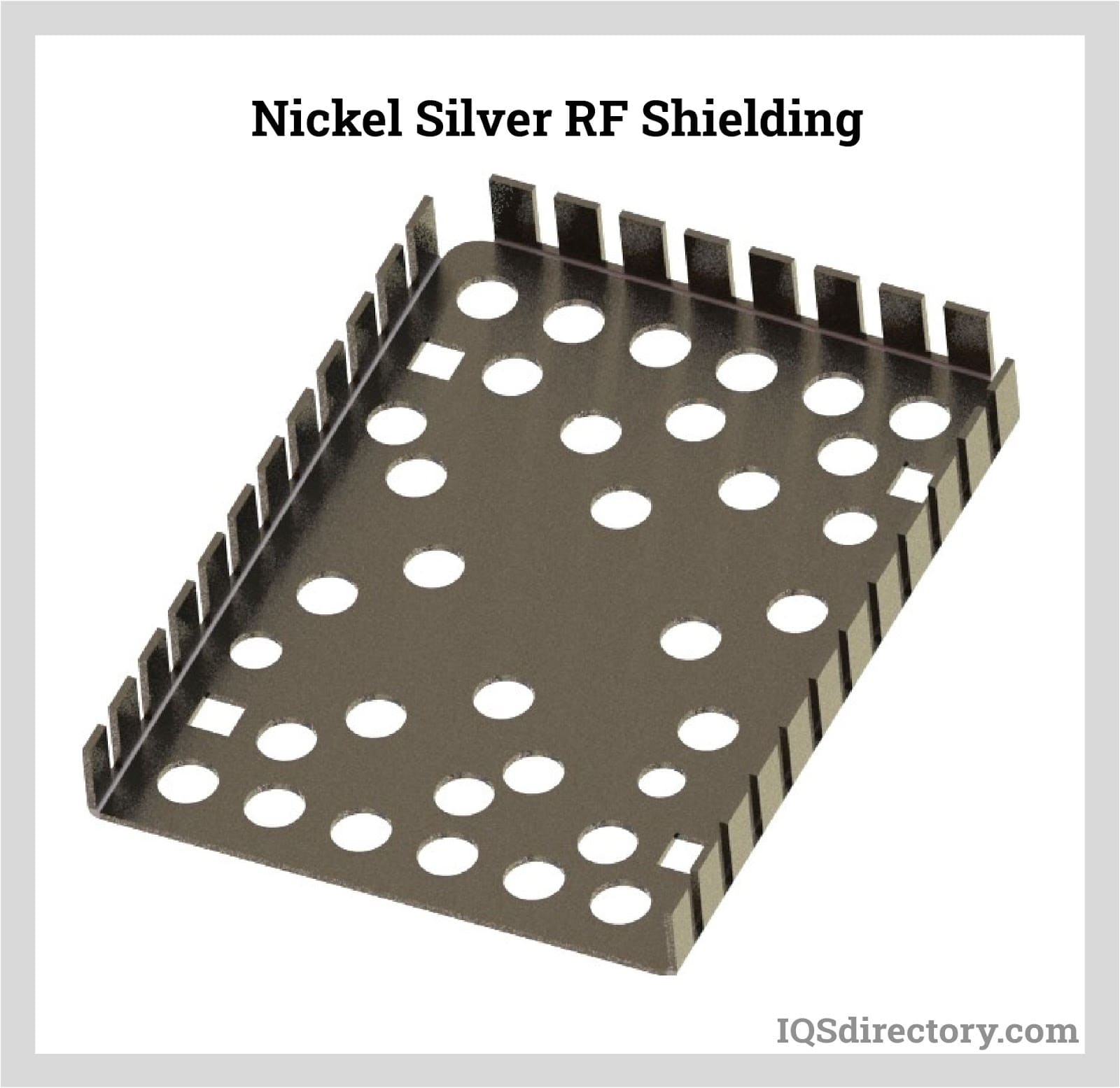

Nickel Silver

Nickel silver, also called copper alloy 770, is a non-magnetic, corrosion-resistant alloy containing nickel, copper, and zinc. It is especially valued in highly corrosive environments and for applications requiring non-magnetic shielding, such as MRI equipment rooms. Nickel silver provides reliable attenuation of RFI in the mid-kHz to GHz range and is often specified by engineers for enclosures and RFI gaskets in medical, military, and high-frequency communication devices.

Conductive Fabrics

Conductive fabrics are lightweight textiles infused or coated with metallic elements such as nickel, copper, silver, gold, or carbon. These fabrics, typically woven from polyester, silk, cotton, or nylon fibers, deliver flexibility and strong shielding efficiency in environments where rigid shields are impractical. Conductive fabrics are frequently used for portable RF shielding enclosures, EMI gaskets, and shielding tents or curtains in laboratories, cleanrooms, and medical facilities. Their versatility and ease of installation make them ideal for temporary or custom RF shielding solutions.

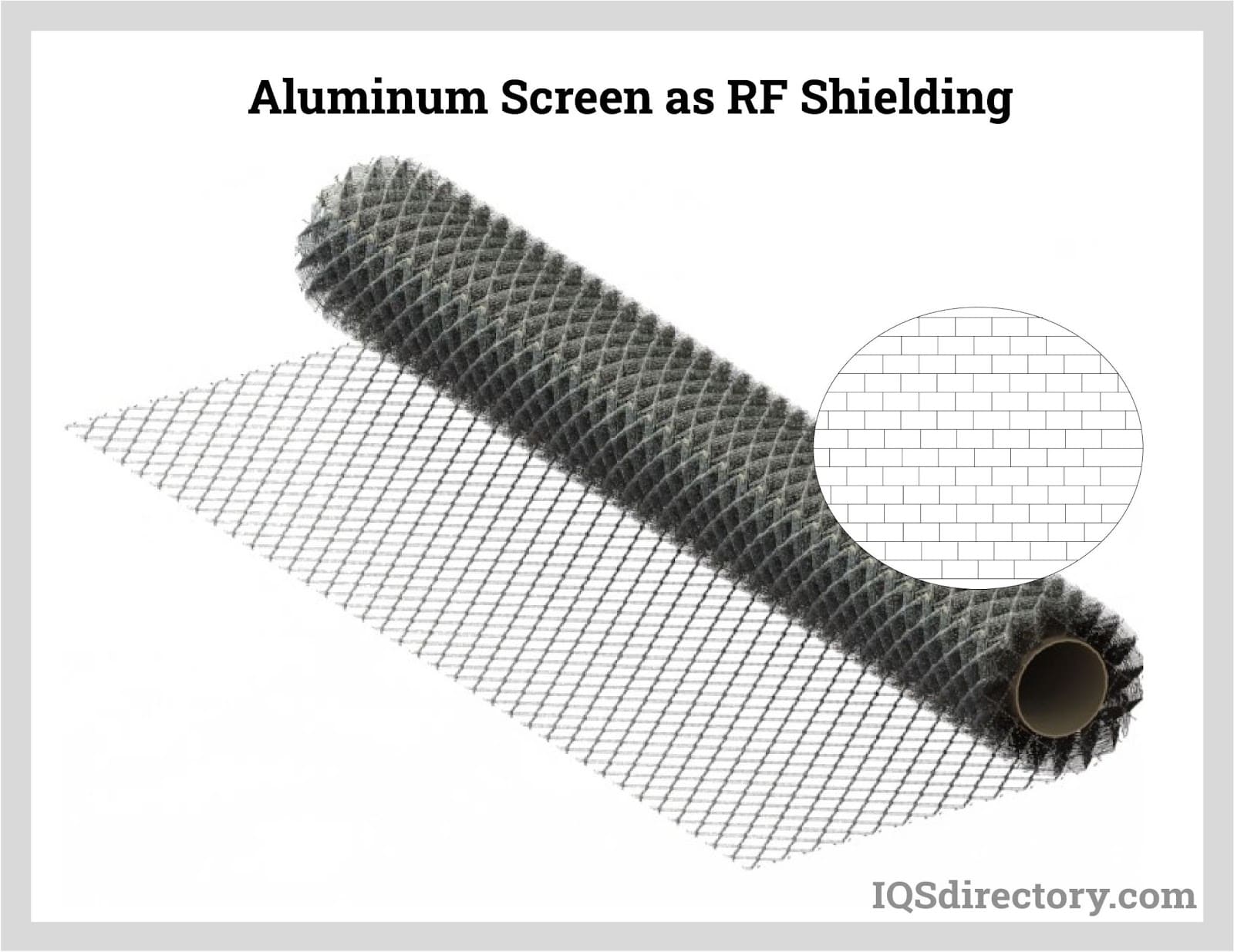

Aluminum

Aluminum is a popular choice for RF shielding due to its lightweight nature, ease of fabrication, and cost-effectiveness. Thin aluminum sheets or foils are effective at blocking low-frequency radio waves, and aluminum enclosures are commonly used to construct electronic device housings that require built-in RF protection. However, aluminum has roughly 50–60% of the conductivity of copper, so thicker shields may be necessary to achieve equivalent attenuation. Aluminum’s corrosion resistance and workability make it suitable for consumer electronics, telecom infrastructure, and automotive components.

Other Specialized Materials

Depending on the application, other materials such as tin-plated copper, silver-plated textiles, mu-metal, and conductive elastomers may be used for enhanced EMI shielding performance or to address specific environmental or frequency challenges. For advanced applications, engineered composites and nanomaterial coatings are emerging as next-generation RF shielding solutions, offering unique combinations of conductivity, weight reduction, and environmental resistance.

Types of RF Interference: Sources, Durations, and Bandwidth Categories

To properly design and implement effective RF shielding, it’s essential to understand the types and sources of electromagnetic interference. Electromagnetic waves consist of oscillating electric and magnetic fields, with their wavelength and frequency defining their place on the electromagnetic spectrum. Electromagnetic interference (EMI) arises when unwanted electromagnetic waves or impulses disrupt the normal operation of electronic equipment, often referred to as electromagnetic noise.

RF interference can be categorized by its source, duration, and bandwidth:

Sources of RF Interference

RF interference can originate from both artificial and natural sources:

- Artificial Sources: These include electronic and electrical devices that emit electromagnetic radiation, such as cell phones, wireless routers, industrial machinery, fluorescent lighting, and power lines. Artificial sources can be intentional (e.g., radio transmitters) or unintentional (e.g., switching power supplies, motors).

- Natural Sources: Astronomical events (solar flares), lightning strikes, static electricity, cosmic noise, and atmospheric disturbances like dust storms and snowstorms are examples of naturally occurring EMI and RFI.

Duration of Interference

RF interference can be continuous or impulsive in nature:

- Continuous RFI: Persistent emissions from a source via radiation or conduction. Examples include broadcast transmitters or industrial machinery operating continuously.

- Impulse RFI: Sudden, short-lived bursts of interference, often caused by switching devices, arc-welding, or lightning. Impulse RFI can disrupt voltage and current balance in nearby or connected devices, leading to data errors and equipment malfunctions.

Bandwidth of Interference

Bandwidth refers to the frequency range over which RFI is present. Understanding the bandwidth is crucial when specifying and designing RF shielding solutions:

- Broadband Interference: Occurs over a wide frequency range with no single discrete signal. Sources can be natural (e.g., the sun interfering with satellite links) or artificial (e.g., arc-welding equipment, power tools). Common coupling mechanisms include:

- Radiative coupling

- Magnetic coupling

- Conductive coupling

- Narrowband Interference: Centered around a specific frequency, such as a radio transmitter interfering with a particular channel or band.

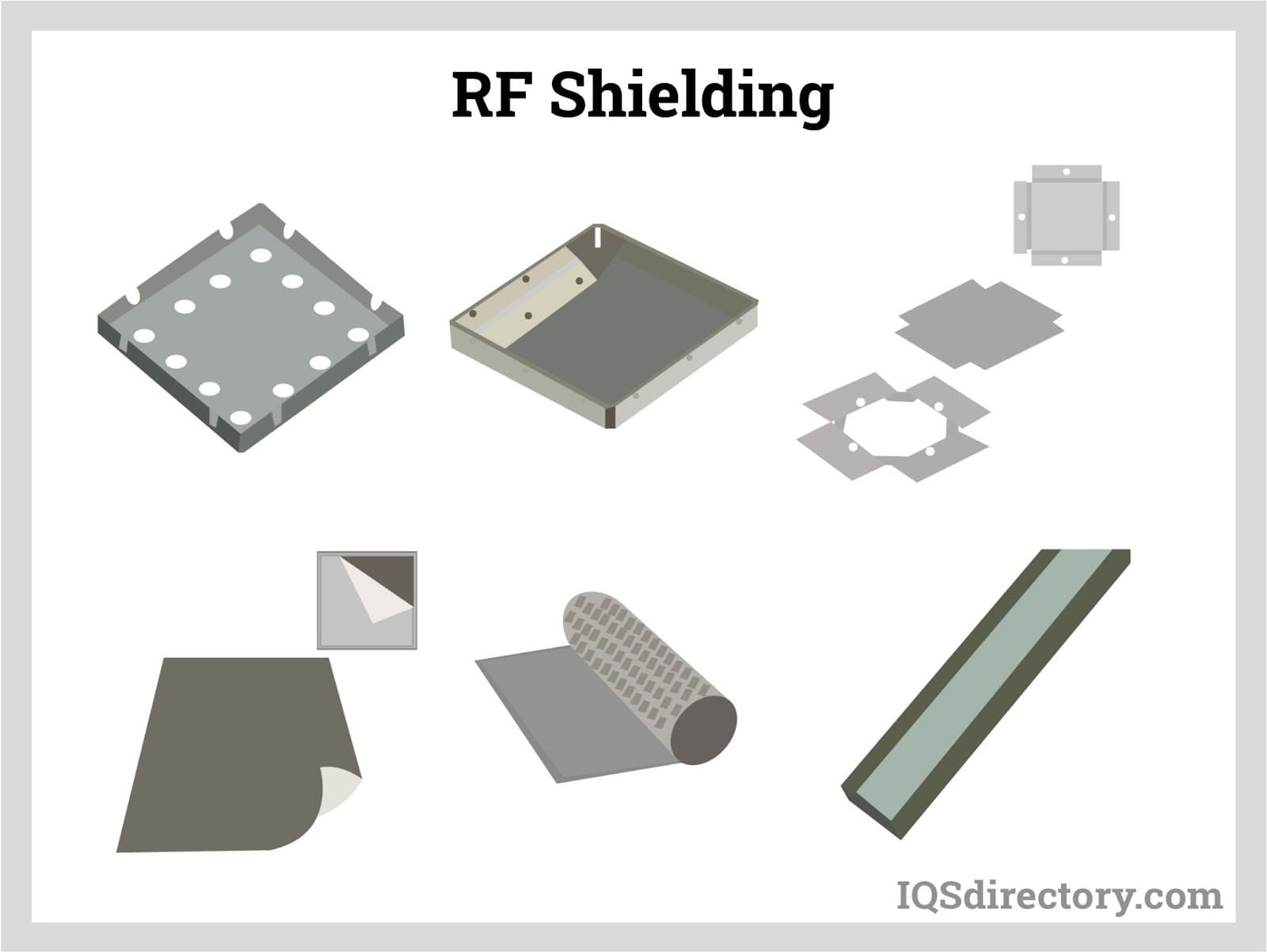

Common Forms and Methods of RF Shielding

There are multiple methods and products available for RF shielding, each optimized for specific use cases, installation requirements, and frequency ranges. Typical RF shielding methods include:

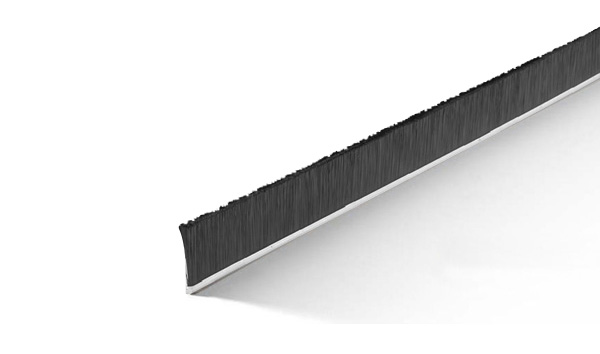

- Cable Shielding: Utilizes braided, foil, or composite shields around power and signal cables to prevent EMI ingress and egress.

- Shielded Vents: Allow airflow or cooling while maintaining electromagnetic attenuation, used in electronic enclosures and HVAC systems.

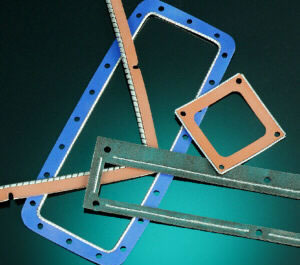

- Gaskets: Provide conductive sealing between shielded panels or enclosure doors, preventing RF leakage at joints and seams.

- Board-Level Shielding: Employs metal cans, fences, or compartmentalized shields on printed circuit boards to isolate sensitive components.

- RF-Shielded Facilities: Entire rooms or buildings lined with conductive layers or mesh to create Faraday cages, commonly used in medical imaging, research, and secure communications.

- Solid Enclosures: Metal cases, racks, or cabinets designed to fully enclose and protect electronic systems from external RF interference.

- Wire Mesh and Screens: Metallic meshes provide flexible, cost-effective shielding for windows, ventilation openings, or temporary barriers.

- O-Rings: Conductive elastomer O-rings provide EMI sealing in harsh or vibration-prone environments.

Key Considerations for Implementing RF Shielding

When planning an RF shielding solution, decision-makers must evaluate several factors to ensure optimal EMI/RFI attenuation and cost-effectiveness:

- Frequency of Concern: Different materials and designs perform better at specific frequencies—identify your target frequency range.

- Environmental Conditions: Consider humidity, temperature, corrosive exposure, and mechanical stresses that may affect shield performance or longevity.

- Shield Continuity and Grounding: Even small gaps or poor grounding can compromise shielding effectiveness. Ensure proper installation and bonding.

- Shielding Effectiveness (SE) Ratings: Compare products based on decibel (dB) attenuation at relevant frequencies.

- Mechanical and Space Constraints: Select materials and forms that fit your application without impeding function or accessibility.

- Regulatory Compliance: Ensure shields meet relevant standards (FCC, CE, MIL-STD, IEC) for your industry and market.

- Cost and Availability: Balance performance needs with budget, considering both initial and lifecycle costs.

Are you wondering: What level of RF shielding do I need for my application?

How do I compare the effectiveness of different shielding materials?

Which RF shielding method is best for my industry?

What are the best practices for RF shield installation and maintenance?

How do I ensure regulatory compliance for my products?

Consulting with experienced RF shielding suppliers and manufacturers can help you answer these questions, ensuring your solution is tailored to your requirements and delivers reliable, cost-effective protection.

Industry Applications and Use Cases for RF Shielding

RF shielding is critical in a wide variety of industries and environments where electromagnetic interference can threaten safety, performance, or data integrity. Common applications include:

- Medical Facilities: MRI suites, X-ray rooms, and operating theaters use specialized RF shields to prevent interference with sensitive diagnostic equipment.

- Telecommunications: Data centers, wireless base stations, and network infrastructure require shielding to ensure signal integrity and reduce crosstalk.

- Consumer Electronics: Smartphones, tablets, laptops, and wearable devices integrate miniature RF shields to comply with EMC standards and prevent device-to-device interference.

- Automotive: Modern vehicles use RF shielding to protect on-board computers, sensors, and infotainment systems from electronic noise.

- Aerospace and Defense: Aircraft, satellites, and military systems rely on EMI shielding for mission-critical communication and navigation reliability.

- Industrial Automation: Factories and process plants deploy shielding to maintain equipment uptime and prevent hazardous malfunctions from EMI/RFI sources.

- Research Laboratories: Faraday cages and shielded rooms ensure accurate scientific measurements and protect experiments from external EMF exposure.

How to Choose the Right RF Shielding Supplier

Choosing the correct RF shielding supplier is pivotal to achieving optimal performance and compliance in your project. Here’s a step-by-step guide for buyers and engineers:

- Assess Your Requirements: Define the frequency range, attenuation level, environmental conditions, and application specifics for your project.

- Research Suppliers: Use our extensive directory of RF shielding suppliers to compare companies, review their business profiles, and evaluate their expertise and capabilities.

- Request Information and Quotes: Utilize our integrated contact forms to reach out directly to suppliers for product details, technical support, or a custom quote.

- Review References and Case Studies: Examine each supplier’s history of projects, certifications, and customer testimonials to ensure they can deliver quality and reliability.

- Utilize Our RFQ Tool: Send your requirements to multiple RF shielding companies simultaneously using our streamlined RFQ form, saving time and ensuring competitive pricing.

Need help comparing RF shielding suppliers? Contact our experts or browse our curated list of top-rated companies to find a partner that matches your technical requirements and budget.

Frequently Asked Questions about RF Shielding

What is the difference between EMI shielding and RF shielding?

While the terms are sometimes used interchangeably, EMI shielding refers to protection against all types of electromagnetic interference (across the entire EM spectrum), whereas RF shielding targets interference in the radiofrequency range (typically 3 kHz to 300 GHz).

How do I test the effectiveness of an RF shield?

Testing typically involves measuring the attenuation (in dB) of electromagnetic signals across the shield using spectrum analyzers and signal generators. Third-party labs and suppliers can provide shielding effectiveness (SE) certification for your installation or product.

Can I retrofit RF shielding into existing equipment?

Yes, many suppliers offer retrofit solutions such as conductive coatings, shielding gaskets, conductive tapes, or modular enclosures that can be added to legacy systems or facilities to improve EMI/RFI protection.

What standards govern RF shielding?

Common standards include FCC Part 15, CE EMC Directive, MIL-STD-461, IEC 61000, and specific industry or application requirements. Ensure your RF shielding solution meets all relevant regulations for your market.

What are the most cost-effective RF shielding solutions?

Cost-effectiveness depends on performance needs, frequency range, and installation complexity. For basic consumer electronics, board-level shields and conductive coatings may suffice. For demanding environments, engineered enclosures or room-level shielding may be justified.

Get Started with RF Shielding Solutions

Whether you’re designing a new product, upgrading existing equipment, or planning a shielded facility, investing in the right RF shielding is essential for performance, safety, and compliance. Explore our RF shielding supplier directory to compare leading manufacturers, request quotes, and access expert guidance for your application.

Looking to learn more? Try search prompts such as:

- “Best RF shielding materials for medical devices”

- “How to block RF interference in data centers”

- “Top RF shielding suppliers near me”

- “EMI vs. RFI: Key differences and solutions”

- “How to test RF shielding effectiveness”

- “Regulatory standards for EMI/RFI shielding”

- “Custom RF shielding solutions for industrial automation”

For personalized advice or a detailed quotation, contact our team of RF shielding experts today and ensure your project is protected from unwanted electromagnetic interference.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services