EMI gaskets offer environmental sealing, thermal insulation, and electromagnetic interference shielding. They are constructed of highly electrically conductive elastomers like silicone or fluorosilicate. Their materials adhere to strict requirements, support a range of fabrication techniques, and can be provided with electrically conductive adhesive backings for simple installation. Read More…

PMT shielding solutions is an industry leader in thin film metallic coatings, providing EMI/RFI shielding for advanced technology applications. With years of experience in vacuum metallization, functional finishes, and a commitment to quality and on-time delivery, you can count on PMT to protect the equipment that protects lives.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

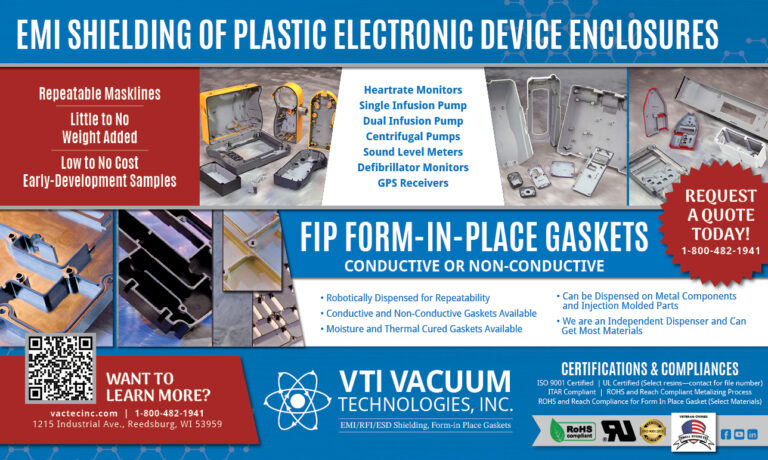

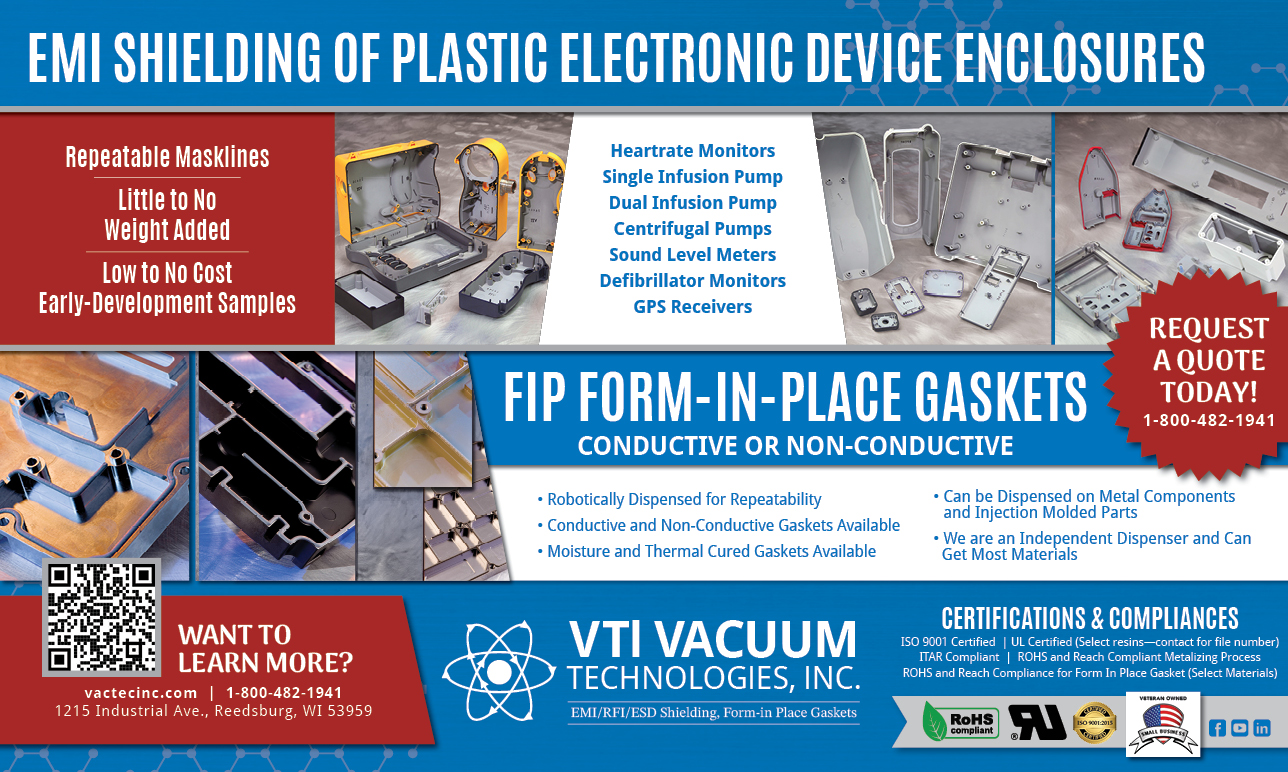

At VTI Vacuum Technologies Inc., we specialize in delivering high-performance EMI shielding solutions that protect sensitive electronics from electromagnetic interference and ensure the reliability of critical systems. As experts in vacuum metallization, we apply precision coatings to plastic enclosures and components, creating conductive barriers that meet or exceed industry shielding...

At V Technical Textiles, we have built our reputation on delivering advanced solutions for electromagnetic interference shielding that protect sensitive equipment and ensure reliability in critical environments. We specialize in designing and manufacturing technical fabrics and materials that meet the demanding requirements of industries where electronic performance, safety, and durability are...

More EMI Gasket Companies

Although there are many different EMI shielding materials, electrically conductive silicones offer exceptional performance and variety to EMI gasket designers. EMI gaskets are critical components used to close the space between two mating surfaces, providing both environmental sealing and electromagnetic interference (EMI) suppression. By blocking out external electromagnetic fields or containing emitted signals, EMI gaskets play a vital role in protecting sensitive electronics from interference that could disrupt device functionality.

When EMI noise—whether conducted or radiated—impacts an EMI gasket, the unwanted signals are neutralized as the gasket conducts the interfering current safely away from sensitive circuitry. This essential electrical conductivity is achieved by incorporating metal-coated particles or conductive fillers into the base silicone, which is naturally an electrical insulator. The result is a specialized gasket that delivers both robust EMI shielding and reliable sealing performance in demanding environments.

What Is an EMI Gasket and How Does It Work?

EMI gaskets, also known as electromagnetic interference shielding gaskets, are engineered sealing solutions designed to prevent electromagnetic energy from leaking into or escaping from electronic devices and enclosures. These gaskets are commonly used in applications ranging from telecommunications, aerospace, and automotive electronics to medical devices and industrial automation equipment. Their primary function is to maintain signal integrity, prevent crosstalk, and ensure compliance with regulatory standards for electromagnetic compatibility (EMC).

How do EMI gaskets block interference? The conductive particles within the gasket form a continuous path for electrical currents, effectively grounding EMI and radio-frequency interference (RFI). This makes EMI gaskets indispensable for any application where electronics must operate reliably in the presence of external or internal electromagnetic fields.

Wondering which EMI gasket is best for your device? Consider the enclosure design, expected EMI frequencies, environmental conditions, and the required level of shielding effectiveness before selecting a gasket type.

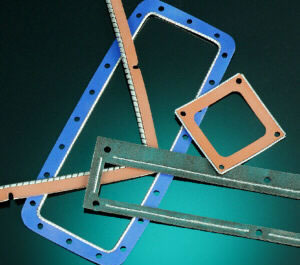

Types of EMI Gaskets

Although most gaskets for EMI shielding are made of electrically conductive elastomers, there are a wide variety of materials and constructions available. Engineers can specify rigid, sponge, or fabric-reinforced materials to improve performance for specific use cases. Thanks to modern manufacturing techniques, EMI shielding gaskets can be produced in virtually any size or configuration, with typical thicknesses starting at 0.003 inches and diameters ranging from 0.250 to 60 inches.

Key decision factors when choosing an EMI gasket include:

- Level of required EMI attenuation

- Environmental sealing needs (dust, moisture, chemical resistance)

- Material compatibility with enclosure surfaces

- Mechanical properties such as compression set and recovery

- Installation method and hardware requirements

Groove Mounted EMI Gasket

Groove mounted EMI gaskets are designed to fit into a machined, extruded, or cast groove within a device enclosure. These gaskets are often fabricated using woven spring temper beryllium copper, a material renowned for its excellent conductivity, mechanical resilience, and spring memory. The unique properties of groove mounted gaskets make them ideal for applications where high shielding effectiveness and repeated cycling are required, such as in aerospace, military, and defense electronics.

Key benefits: Groove mounted gaskets can achieve shielding performance up to 165 dB, making them a top choice for environments with strong EMI or RFI exposure. Their robust design can also compensate for enclosure irregularities and maintain a consistent seal over time.

Common use cases: Avionics systems, military-grade communication equipment, radar enclosures, and high-reliability industrial control panels.

Multiple Sealed Grooved Mounted Gaskets

Multiple sealed grooved mounted EMI gaskets combine EMI shielding and environmental protection within a single solution. By incorporating both conductive and non-conductive sealing elements, these gaskets provide superior barrier performance against moisture, dust, and chemical ingress while attenuating electromagnetic interference.

Typical insulation levels: 86 to 165 dB, making them suitable for high-quality sealing in medical, automotive, and industrial electronic enclosures.

Silicone Grooved Mounted Gaskets in Stainless Steel

Silicone grooved mounted gaskets, reinforced with stainless steel or aluminum, offer a lightweight and corrosion-resistant solution for EMI and environmental sealing. These gaskets are especially effective where minimal closure force is required—typically less than or equal to 2 pounds per linear inch. The combination of a silicate-based elastomer and alloy metals ensures both flexibility and shielding performance.

Key advantages: Ease of installation, resistance to compression set, high durability, and the option to tailor shielding effectiveness with aluminum or stainless steel fillers.

Industry applications: Consumer electronics, medical devices, and any enclosure where weight and corrosion resistance are critical design factors.

Conductive Fabric-Over-Foam Gaskets

For applications requiring flexibility and cost-effectiveness, conductive fabric-over-foam gaskets are a popular choice. These gaskets combine a resilient foam core with a metallized fabric exterior, delivering both compressibility and effective EMI shielding. Fabric-over-foam gaskets are widely used in telecommunications equipment, server racks, and portable electronics where frequent access and repeated compression cycles are common.

Advantages: Lightweight, easy to install, customizable profiles, and excellent performance for mid-frequency EMI attenuation.

EMI Shielding O-Rings and Custom Profiles

O-ring EMI gaskets and custom profile gaskets are engineered to fit specific enclosure geometries. Made from conductive silicone or fluorosilicone, these gaskets can be extruded, molded, or die-cut to match precise design requirements. O-ring EMI gaskets are typically used in connectors, access panels, and sealing flanges, ensuring reliable EMI/RFI shielding alongside environmental protection.

Looking for a custom EMI gasket solution? Contact manufacturers to discuss your unique dimensions, material requirements, and performance specifications to ensure optimal fit and function.

Shielding for Surface Mounted EMI

Surface-mounted EMI shielding gaskets are ideal when there is sufficient space on the enclosure surface for installation. These gaskets often feature a silicon elastomeric extrusion, which provides an effective low-force environmental seal in addition to EMI attenuation. Shielding effectiveness typically ranges from 86 to 165 dB, depending on material selection and gasket design.

Common applications: Network equipment, data centers, telecommunications base stations, and large industrial enclosures.

Installation tip: Surface-mounted EMI gaskets can be supplied with pressure-sensitive adhesive (PSA) backings for easy positioning and assembly. This reduces installation time and ensures consistent contact with enclosure surfaces for maximum shielding performance.

Constructing an EMI Gasket

The design and manufacturing process for an EMI gasket is determined by the intended function, required performance, and enclosure geometry. Understanding the construction methods can help engineers and procurement professionals make informed choices when sourcing EMI shielding solutions.

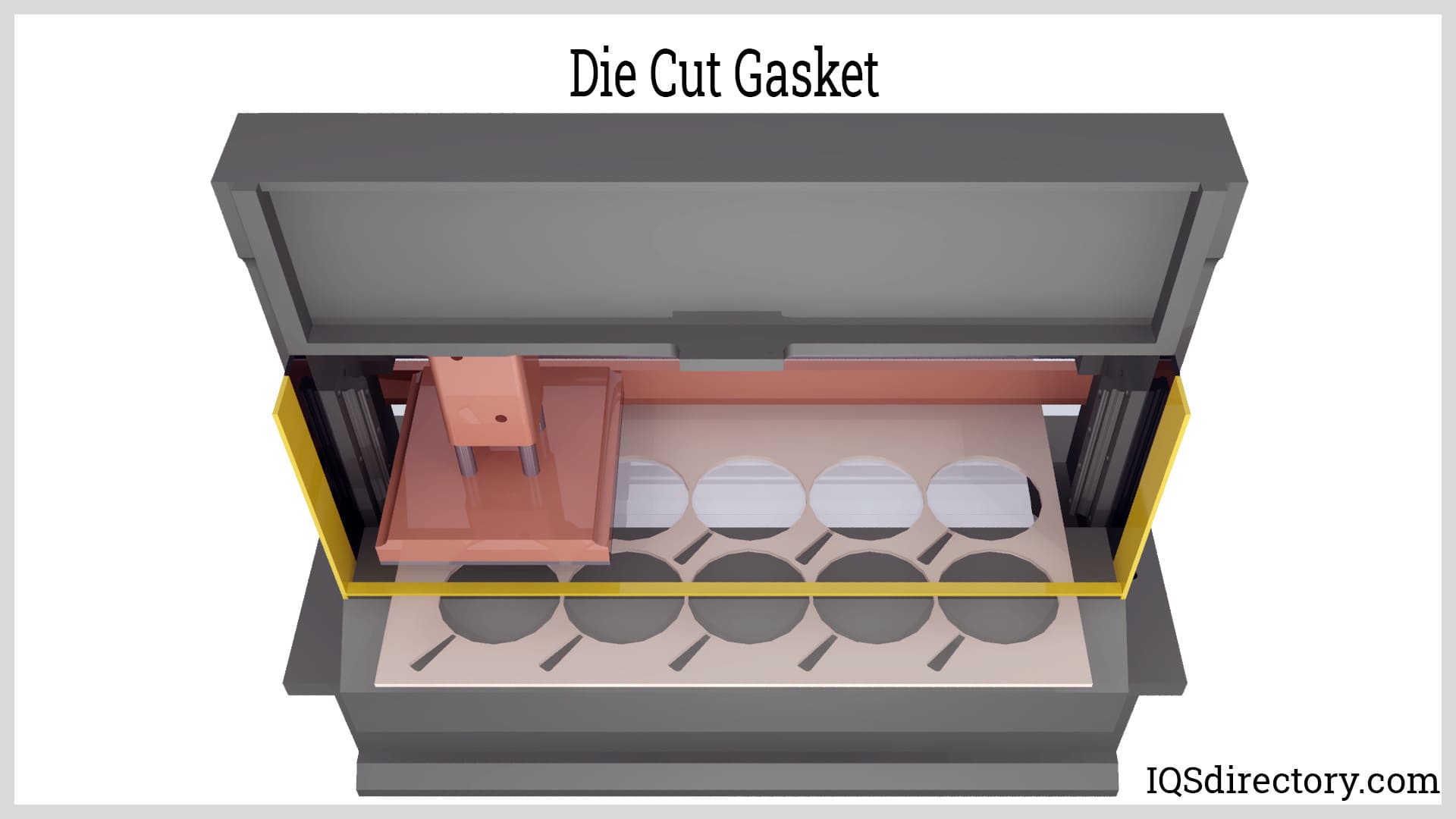

Die-Cutting

Die-cutting is a widely used method for producing EMI gaskets with precise shapes. In this process, sheets of conductive elastomer or fabric are cut using a die to create custom gasket profiles. Die-cut gaskets are ideal for flat, complex, or irregular surfaces and offer high repeatability for large production runs.

Digital Die-Less Manufacturing

Digital die-less cutting uses advanced computer-controlled equipment to quickly and accurately produce gaskets without the need for traditional tooling. This method maximizes material utilization, reduces waste, and enables rapid prototyping or low-volume production runs. It's especially beneficial for custom designs and short lead times.

Compression Molding

Compression molding involves shaping ready-to-mold conductive compounds within a mold to produce a finished EMI gasket. This process allows for the creation of complex three-dimensional gasket shapes and integrated features, such as retention clips or specialized sealing profiles. Compression molding is ideal for high-volume production and applications requiring superior consistency and mechanical strength.

Did you know? Compression-molded EMI gaskets yield less material waste compared to die-cut parts, especially in designs with central cutouts or intricate geometries.

Extrusion

Extrusion is a continuous manufacturing process where conductive silicone or elastomer is forced through a die to produce long, uniform profiles. Extruded EMI gasket profiles can be cut to length and supplied as strips, cords, or O-rings, making them suitable for perimeter sealing and large enclosures.

Adhesive-Backed and Framed EMI Gaskets

Many EMI gaskets can be supplied with pressure-sensitive adhesive backings, enabling fast, tool-free installation. Framed gaskets utilize a rigid or semi-rigid frame to support the gasket material, providing enhanced alignment, mechanical stability, and consistent compression during assembly.

Ask yourself: Do you need a removable or permanent EMI gasket? Adhesive-backed options are ideal for quick installation and easy maintenance, while framed gaskets offer robust, long-term performance in mission-critical environments.

Benefits of EMI Gaskets in Electronics Design

EMI gaskets deliver a multitude of benefits for electronics design engineers, enclosure fabricators, and OEMs. Understanding these advantages can help inform your decision when specifying a shielding solution:

- Effective EMI/RFI attenuation: Protects sensitive circuits from both incoming and outgoing interference.

- Regulatory compliance: Ensures products meet FCC, CE, and other global EMC standards.

- Environmental sealing: Shields against dust, moisture, chemicals, and other contaminants.

- Mechanical protection: Provides vibration damping, shock absorption, and structural support.

- Design flexibility: Available in a wide range of materials, profiles, and sizes for virtually any application.

- Cost-effectiveness: Reduces system-level EMI mitigation costs by addressing interference at the enclosure level.

Evaluating EMI gasket solutions? Compare the total cost of ownership, from material selection to installation and long-term maintenance, to maximize the value of your shielding investment.

Industry Applications and Use Cases

EMI shielding gaskets are critical in a wide array of industries and technologies. Here are some of the most prominent sectors where EMI gasket solutions are indispensable:

- Aerospace and Defense: Shielding avionics, navigation systems, and secure communications from high-intensity electromagnetic fields.

- Automotive Electronics: Protecting ECUs, infotainment systems, and advanced driver-assistance systems (ADAS) from EMI/RFI for reliable operation.

- Telecommunications: Ensuring signal integrity in network infrastructure, base stations, and 5G equipment.

- Medical Devices: Maintaining safety and compliance in diagnostic equipment, life-support systems, and wearable health monitors.

- Industrial Automation: Shielding programmable logic controllers (PLCs), sensors, and robotics from electromagnetic noise.

- Consumer Electronics: Reducing interference in smartphones, tablets, and IoT devices, enhancing user experience and regulatory compliance.

Curious about EMI gasket performance in your specific industry? Explore detailed case studies and application guides or consult with an EMI gasket manufacturer for tailored recommendations.

Key Considerations When Selecting EMI Gaskets

Selecting the right EMI gasket involves balancing technical requirements with practical constraints. Be sure to assess the following criteria:

- Shielding effectiveness: Measured in decibels (dB), this indicates the gasket’s ability to attenuate EMI/RFI at required frequencies.

- Compression force: The amount of pressure needed to achieve a reliable seal without damaging enclosure components.

- Material compatibility: Ensure the gasket material is chemically and galvanically compatible with your enclosure substrates to prevent corrosion or degradation.

- Operating environment: Consider temperature extremes, humidity, UV exposure, and chemical resistance.

- Mechanical durability: Resistance to compression set, repeated cycling, and vibration.

- Installation method: Evaluate whether adhesive-backed, groove-mounted, or other configurations best suit your assembly process.

- Certifications: For mission-critical applications, check for compliance with military, aerospace, or medical device standards.

Need help determining the right EMI gasket? Use online selection tools, consult manufacturer datasheets, or contact technical support for expert guidance tailored to your application.

Choosing the Correct EMI Gasket Manufacturer

To achieve the best results when purchasing EMI gaskets, it’s essential to partner with a reputable EMI gasket manufacturer. Here are some steps to guide your selection process:

- Compare multiple companies using a comprehensive directory of EMI gasket manufacturers.

- Review each manufacturer’s business profile to understand their areas of expertise, capabilities, and industry experience.

- Use contact forms to request additional information, technical datasheets, or a personalized quote.

- Take advantage of patented website previewers to assess manufacturer specialties, certifications, and production technologies.

- Submit a Request for Quote (RFQ) to multiple suppliers using a unified form for efficient communication and faster responses.

Ready to source EMI gaskets for your next project? Start by evaluating manufacturers based on product quality, lead times, customization options, and customer support. Don’t hesitate to ask for references, case studies, or sample gaskets to validate fit and performance before making a purchase.

Further questions? Explore our resources, FAQs, and expert articles to deepen your understanding of EMI shielding solutions, or reach out directly to a supplier for personalized assistance.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services