Typically manifested as an enclosure, signal or coating, EMI shielding, also known as radiation shielding, is a service provided in order to prevent or block electromagnetic interference. Electromagnetic interference, commonly known as EMI is a kind of electromagnetic radiation that can damage, lessen or interrupt the functions of electronic devices and electronic equipment. EMI can travel along conductors, electrical circuits and wires. Similarly, radio frequency interference (RFI), which is radiated electromagnetic “noise,” travels through the air as radio waves, where it causes the same problems as EMI. Read More…

PMT shielding solutions is an industry leader in thin film metallic coatings, providing EMI/RFI shielding for advanced technology applications. With years of experience in vacuum metallization, functional finishes, and a commitment to quality and on-time delivery, you can count on PMT to protect the equipment that protects lives.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

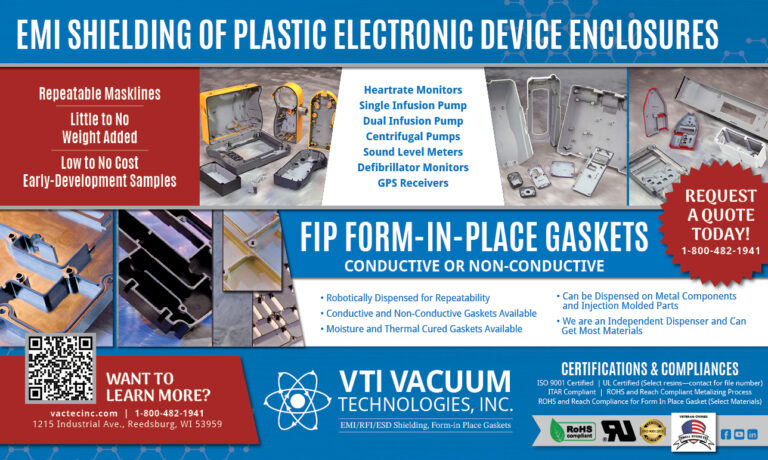

At VTI Vacuum Technologies Inc., we specialize in delivering high-performance EMI shielding solutions that protect sensitive electronics from electromagnetic interference and ensure the reliability of critical systems. As experts in vacuum metallization, we apply precision coatings to plastic enclosures and components, creating conductive barriers that meet or exceed industry shielding...

At V Technical Textiles, we have built our reputation on delivering advanced solutions for electromagnetic interference shielding that protect sensitive equipment and ensure reliability in critical environments. We specialize in designing and manufacturing technical fabrics and materials that meet the demanding requirements of industries where electronic performance, safety, and durability are...

More EMI Shielding Companies

Applications

Radiation shielding, a cornerstone of electromagnetic interference (EMI) and radio frequency interference (RFI) mitigation, serves critical roles across a spectrum of industries, ensuring protection from both ionizing and non-ionizing radiation. Within the medical field, EMI and radiation shielding are pivotal in radiology, radiation oncology, diagnostic imaging, and nuclear medicine. Shielding solutions safeguard healthcare providers and patients from X-rays, gamma rays, and other potentially hazardous radiation types during imaging, therapy, and diagnostic procedures, ensuring both regulatory compliance and patient safety.

In the nuclear sector, radiation shielding is indispensable for protecting workers and the public during reactor operation, nuclear fuel handling, transport, and radioactive waste storage. Shielding is integral to the design and infrastructure of nuclear power plants, controlling radiation release and supporting safe management of radioactive materials. Compliance with rigorous safety standards and regulations, such as those from the Nuclear Regulatory Commission (NRC), is paramount, making advanced EMI shielding solutions a necessity in this industry.

Shielding is also vital in Non-Destructive Testing (NDT) and other industrial applications. Industries such as aerospace, automotive, manufacturing, and infrastructure rely on radiography, computed tomography (CT), and other imaging technologies to verify the integrity of materials and components. Here, radiation and EMI shielding protect both operators and sensitive equipment from harmful radiation exposure, supporting quality assurance and industrial safety.

In industrial sterilization and material testing, robust radiation and EMI shielding is essential for safeguarding operators and bystanders. For example, in the food industry, gamma irradiation ensures food preservation and safety by eliminating pathogens, with shielding solutions protecting both workers and consumers. Similarly, in pharmaceutical manufacturing, controlled environments require effective EMI/RFI shielding to maintain product integrity and comply with Good Manufacturing Practices (GMP).

Within space exploration, effective radiation and EMI shielding emerge as critical necessities due to the absence of Earth’s protective atmosphere. Spacecraft, satellites, and space habitats must incorporate advanced shielding materials to protect astronauts and onboard electronics from cosmic radiation, solar flares, and intense electromagnetic fields during extended missions. NASA and other space agencies prioritize high-performance EMI shielding to ensure mission success and crew safety.

Scientific research environments, such as particle accelerators, research laboratories, and universities, also rely on sophisticated radiation and EMI shielding. These facilities generate ionizing radiation and high-frequency electromagnetic fields during experiments. Shielding solutions protect researchers, equipment, and data integrity, facilitating groundbreaking discoveries while maintaining a safe workspace.

EMI and radiation shielding extend beyond industrial and medical sectors to encompass security applications like baggage scanners, cargo inspection systems, and border security at airports, ports, and government facilities. These systems utilize radiation sources for security scans, employing shielding to protect operators, inspectors, and the public from exposure.

Overall, radiation and EMI shielding are indispensable across diverse industries—including medical, nuclear energy, aerospace, defense, manufacturing, telecommunications, research, and security. Their significance spans from protecting human health and the environment to ensuring the operational reliability of critical infrastructure and sensitive electronics. For organizations seeking robust shielding solutions, understanding the full range of applications and industry requirements is essential to making informed decisions.

Products Produced

Our comprehensive EMI shielding services encompass a diverse range of specialized products designed to address electromagnetic compatibility (EMC) challenges. Common EMI shielding products include:

- EMI Enclosures (Faraday cages) — Provide complete shielding for electronic equipment by enveloping devices in conductive materials, blocking both incoming and outgoing EMI/RFI. Used in server rooms, laboratories, and sensitive medical equipment.

- EMI Coatings — Conductive coatings applied to non-conductive surfaces (e.g., plastic housings, cables) using spraying, brushing, or painting. These coatings combine carrier materials with metals like copper, nickel, or chromium alloys to form a metallic ink, providing a flexible shielding solution for electronics and electrical housings.

- EMI Filters — Passive electronic components designed to mitigate conducted EMI. These filters block high-frequency electromagnetic noise from power lines, data lines, and signal cables while allowing legitimate signals to pass. EMI/RFI filters are crucial in power supplies, medical devices, telecom equipment, and industrial automation.

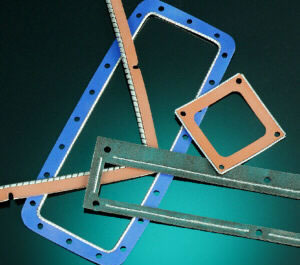

- EMI Gaskets — Combine conductive rubber (e.g., silicone, neoprene) with shielding metals to seal enclosure gaps and seams, preventing EMI leaks and ingress. EMI gaskets are available in custom shapes and sizes, ensuring compatibility with diverse enclosure designs.

- RF Absorbers — Specialized materials (often foam or elastomer-based, impregnated with conductive particles) that absorb or attenuate radio-frequency interference (RFI) and microwave energy, reducing reflection and transmission. Used in anechoic chambers and electronic assemblies.

- Conductive Fabrics — Metalized textiles (e.g., copper, silver-plated nylon or polyester) used in flexible shielding applications, including room linings, EMI/RFI gaskets, tapes, and wearable electronics. Conductive fabrics can be woven, knitted, or nonwoven and offer excellent flexibility and conformability.

- Shielding Tapes, Foils, and Laminates — Used for spot shielding, cable wrapping, and field retrofits, these products provide quick and effective EMI/RFI containment.

EMI Enclosure

EMI enclosures, often referred to as Faraday cages, function by fully enveloping the equipment they shield in a conductive material. These enclosures may be solid or, where visibility or airflow is needed, constructed from perforated metal. The critical requirement is that perforations are smaller and more closely spaced than the wavelength of the targeted electromagnetic waves, ensuring effective attenuation. For example, the perforated metal sheets in a microwave oven prevent microwaves from escaping while allowing light through for visibility. EMI enclosures are widely used in server rooms, medical imaging suites, and secure communication facilities to protect sensitive electronics from both inbound and outbound EMI/RFI.

EMI Coating

EMI coatings offer versatile, scalable shielding solutions by combining carrier materials with conductive metals such as copper, nickel, or chromium alloys to form a metallic ink. These coatings are applied via spraying, brushing, or painting to the interior of non-conductive enclosures, wires, and device housings. EMI coatings are popular in electronics manufacturing, automotive assemblies, and consumer devices where retrofitting or lightweight shielding is required.

EMI Filter

An EMI filter is a passive component engineered to block unwanted conducted or radiated electromagnetic interference from power and signal lines. By diverting or attenuating high-frequency noise, EMI filters ensure smooth operation of sensitive electronics. Typical applications include power supplies, industrial automation systems, and medical devices, where regulatory compliance and operational stability are critical.

EMI Gasket

EMI gaskets are engineered from conductive elastomers, such as silicone or neoprene, combined with metallic fillers (e.g., silver, nickel, aluminum). These gaskets seal enclosure seams, connectors, and access panels, blocking EMI from entering or exiting equipment enclosures. They are especially valuable in telecommunications, defense, and aerospace electronics, where environmental sealing and EMI protection are both critical.

RF Absorber

RF absorbers (radar and microwave absorbers) are designed to absorb electromagnetic energy, preventing RFI from penetrating shielded environments. They are used in anechoic chambers for EMC testing, inside electronic enclosures for internal noise suppression, and in aerospace applications to reduce radar cross-section.

Conductive Fabric

Conductive fabrics, or metalized fabrics, incorporate metallic fibers or coatings onto textile substrates like nylon or polyester. These fabrics offer lightweight, flexible EMI/RFI shielding and are used for room linings, EMI gaskets, tapes, wearable electronics, and specialized garments for personnel working in high-EMI environments. Their ability to conform to complex shapes makes them ideal for custom shielding solutions.

Searching for a specific EMI shielding product?

- What is the best EMI enclosure for your application?

- How do EMI coatings compare to metal enclosures?

- Which EMI gasket material suits your environment?

- Looking for custom RF absorber solutions?

Contact us or browse our directory to compare products from leading EMI shielding manufacturers.

History

The history of EMI shielding dates back to the invention of the Faraday cage by Michael Faraday in 1836, inspired by Benjamin Franklin’s earlier experiments in 1755, which demonstrated that electric charges could be blocked by metallic enclosures. Faraday constructed a room coated with metal foil and used an electrostatic generator to confirm that the interior remained free from electric charge, proving the effectiveness of electromagnetic shielding.

With the rise of radio technology and wireless communications in the early 20th century, concerns about electromagnetic interference (EMI) and radio frequency interference (RFI) grew. In response, the International Electrotechnical Commission (IEC) convened in Paris, leading to the formation of the International Special Committee on Radio Interference (CISPR), the pioneering regulatory body for EMI standards. The establishment of CISPR laid the groundwork for today’s electromagnetic compatibility (EMC) regulations, influencing global standards for EMI and RFI control.

By 1979, the United States began enforcing EMI regulations, followed by similar initiatives in the European Union during the mid-1980s. The proliferation of electronic devices—ranging from computers and mobile phones to automotive electronics and medical equipment—has made EMI shielding a necessity. Modern electronics are increasingly sensitive to electromagnetic noise; hence, engineers continue to innovate with advanced materials and miniaturized shielding solutions to meet strict EMC requirements in compact, high-density designs.

Today, EMI shielding is a foundational technology in the design and manufacture of electronics, telecommunications, aerospace systems, medical devices, and more, ensuring performance reliability and compliance with international standards.

Materials Process

EMI and RFI shielding solutions rely on a variety of materials, each selected for its specific electromagnetic properties. Typically, the shielding process necessitates a conductive surface to intercept, absorb, or reflect electromagnetic waves. Key materials include:

- Copper — Renowned for its superior conductivity, copper is highly effective at blocking and attenuating EMI and RFI across a broad frequency spectrum. Its malleability makes it ideal for custom enclosures, gaskets, and conductive coatings, although it is more expensive than alternatives.

- Steel — Both carbon steel and stainless steel offer excellent magnetic permeability, making them effective against low-frequency EMI. Steel is valued for its strength, durability, and cost-effectiveness in fabrication of enclosures, panels, and structural shielding.

- Aluminum — Lightweight, corrosion-resistant, and highly conductive, aluminum is widely used in the electronics, aerospace, and automotive industries for EMI shielding enclosures and panels. It is especially effective at higher frequencies and offers an excellent strength-to-weight ratio.

- Nickel — Prized for its magnetic properties, durability, and electrical conductivity, nickel is used both as a standalone shield and as an alloying component. Nickel-based coatings and alloys are common in harsh environments or where corrosion resistance is essential.

- MuMetal® — This proprietary alloy (mainly nickel, iron, copper, molybdenum) boasts exceptionally high magnetic permeability, making it the industry standard for shielding against low-frequency magnetic fields. MuMetal® is commonly used in sensitive laboratory, medical, and precision instrumentation applications.

- Conductive Rubbers — Elastomers like silicone and neoprene, infused with conductive particles (silver, nickel, carbon), are used to fabricate EMI gaskets and seals. Silicone offers flexibility and resilience over a broad temperature range, while neoprene is valued for its compression strength and environmental resistance.

Manufacturers often combine these materials to optimize performance, cost, and environmental resilience. For example, an aluminum enclosure may be paired with a conductive rubber gasket to ensure a continuous EMI shield around access panels or doors.

Advances in material science have also led to the development of nanomaterial-based shields (using carbon nanotubes or graphene) and composite materials that offer lightweight, flexible, and highly effective EMI/RFI suppression for next-generation electronics and wearable devices.

Wondering which material is best for your EMI shielding needs?

- What are the pros and cons of copper vs. aluminum for EMI/RFI shielding?

- When should you specify MuMetal® for magnetic field shielding?

- How do conductive rubbers compare in performance and cost?

Explore our resource guides or contact our materials experts for personalized recommendations.

How It Works

EMI shielding functions by utilizing conductive or magnetic materials to create a physical barrier that intercepts, absorbs, or redirects electromagnetic waves. When properly designed and installed, shielding materials prevent unwanted electromagnetic energy from entering or exiting electronic devices, circuits, or enclosures. The core mechanisms include:

- Reflection — Conductive surfaces (e.g., copper, aluminum) reflect incoming electromagnetic waves, sending them away from sensitive components.

- Absorption — Magnetic materials (e.g., MuMetal®, ferrites) and certain composites absorb electromagnetic energy, converting it to heat or dissipating it harmlessly.

- Redirection — Shielding can redirect electromagnetic fields to ground, preventing them from interfering with device operation.

By enveloping devices or circuits with EMI shielding, manufacturers create a controlled environment that neutralizes the impact of external and internal electromagnetic radiation. This is essential for maintaining signal integrity, reducing cross-talk, and ensuring the reliability of sensitive electronics amid growing electromagnetic noise in modern environments.

Design Considerations

Designing effective EMI shielding solutions requires careful consideration of several factors:

- Shielding Effectiveness (Attenuation) — Determine the level of EMI attenuation required based on the device’s sensitivity and the strength of electromagnetic fields in the application environment.

- Application Scope & Dimensions — Assess the size, shape, and physical constraints of the device or enclosure. Select from gaskets, tapes, coatings, or full enclosures as appropriate.

- Flexibility & Conformability — For irregular shapes or equipment with moving parts, choose materials and designs that can flex without losing shielding performance.

- Compliance with Standards — Ensure solutions meet industry-specific EMI/EMC regulations, such as FCC, CE (Conformité Européenne), CISPR, or military standards (MIL-STD).

- Material Selection — Balance electrical conductivity, magnetic permeability, cost, mechanical durability, and environmental impact to select optimal shielding materials.

- Installation & Maintenance — Consider ease of installation, field retrofitting, and long-term performance, especially in mission-critical or high-reliability applications.

Customizing the shielding solution to the application’s unique requirements ensures optimal electromagnetic compatibility, device reliability, and regulatory compliance.

Questions to ask when specifying EMI shielding:

- What frequency range are you shielding against?

- Are there weight or space limitations?

- What are the environmental exposure and durability requirements?

- Does your application require custom gaskets, coatings, or enclosure designs?

Contact our team for support with design calculations, material selection, and regulatory compliance.

Variations and Similar Services

In addition to conventional EMI shielding, alternative technologies and services are available to meet specialized needs:

- Vacuum Metallization — A process where conductive metal (such as aluminum) is vaporized in a vacuum chamber and then condensed onto a substrate, forming a thin, uniform shielding layer. This technique is often used for plastic housings, automotive parts, and decorative EMI/RFI shielding.

- Electroplating — Depositing a thin metal layer (e.g., copper, silver, gold) onto a non-conductive surface to enhance conductivity and EMI shielding performance.

- Conductive Paints & Adhesives — Used for spot shielding, cable repairs, and retrofits where traditional enclosures are impractical.

- Shielded Cables & Connectors — Incorporate internal shielding layers and conductive terminations to prevent conducted and radiated EMI in data and power transmission.

- Ferrite Beads & Cores — Suppress high-frequency EMI on cables and power lines by absorbing and dissipating unwanted energy.

Choosing the right EMI shielding variation depends on the application, performance requirements, and cost constraints.

Benefits

Investing in high-quality EMI shielding yields numerous benefits, including:

- Health Protection — EMI shielding safeguards humans from harmful electromagnetic fields and radiation, reducing risks ranging from minor discomfort (tingling, headaches) to serious health effects such as tissue heating, burns, or increased cancer risk associated with long-term exposure.

- Equipment Performance & Reliability — Shielding prevents malfunctions, data corruption, and downtime in sensitive electronics, supporting optimal performance in medical devices, industrial controls, aerospace systems, and telecommunications infrastructure.

- Regulatory Compliance — Meeting EMI/EMC standards avoids legal penalties, product recalls, and market access barriers, enabling products to be sold globally.

- Product Durability — EMI shielding protects circuits and components from electromagnetic stress, extending equipment lifespan and reducing maintenance costs.

- Sustainability & Recyclability — Many shielding materials (e.g., metals, certain elastomers) are recyclable, supporting sustainability initiatives and lowering total cost of ownership.

Effective EMI shielding also enhances customer satisfaction by ensuring safe, reliable, and compliant products.

Things to Consider

EMI shielding is a mission-critical investment, and selecting the right service provider is essential to project success. With a crowded marketplace, it’s important to evaluate EMI shielding suppliers based on expertise, product range, certifications, customer service, and track record.

To simplify your search, we’ve curated a list of leading EMI shielding companies. Each provider is profiled with in-depth information, contact details, and direct website links. Our listings cover a wide variety of manufacturers and suppliers, allowing you to compare offerings, capabilities, and application expertise.

-

How to choose an EMI shielding provider:

- Research company profiles and assess experience in your industry (e.g., medical, aerospace, defense, electronics manufacturing).

- Examine product portfolios, from custom enclosures and coatings to gaskets and filters.

- Review certifications (ISO, ITAR, RoHS, REACH, etc.) and regulatory compliance expertise.

- Contact three or four providers to discuss your requirements, lead times, budget, and specific compliance needs.

- Request quotes, sample products, or technical consultations to evaluate fit and service quality.

- Pro Tip: Consider long-term support, field service, and warranty options when making your final selection.

After gathering information and engaging with providers, choose the partner that best aligns with your technical, quality, and business requirements. Reach out for a quote or schedule a call to start your EMI shielding project with confidence.

Ready to request a quote for EMI shielding?

Use our Request a Quote tool or contact leading providers directly for personalized solutions tailored to your project.

Explore more industry solutions:

- Check out our Clean Rooms website

- Check out our Magnets website

For detailed technical guides, application case studies, and the latest news on EMI shielding innovations, browse our resource library or contact our technical support team.

What industries rely on EMI and radiation shielding?

EMI and radiation shielding are essential in industries such as medical, nuclear energy, aerospace, defense, manufacturing, telecommunications, research, infrastructure, and security. These sectors use shielding to protect people, equipment, and data from harmful electromagnetic and ionizing radiation.

What are the common products used for EMI shielding?

Common EMI shielding products include EMI enclosures (Faraday cages), EMI coatings, EMI filters, EMI gaskets, RF absorbers, conductive fabrics, and shielding tapes, foils, and laminates. Each is designed to address specific electromagnetic compatibility challenges.

Which materials are most effective for EMI and RFI shielding?

Effective materials include copper, steel, aluminum, nickel, MuMetal®, and conductive rubbers. The choice depends on desired conductivity, magnetic permeability, frequency range, and environmental requirements. Nanomaterials and composites are also used in advanced applications.

How does EMI shielding work?

EMI shielding works by using conductive or magnetic materials to reflect, absorb, or redirect unwanted electromagnetic waves. This prevents electromagnetic energy from entering or exiting devices and ensures signal integrity, device reliability, and compliance with EMC standards.

What are the key factors to consider when designing EMI shielding solutions?

Consider shielding effectiveness, device size and shape, material selection, compliance with industry standards, installation and maintenance requirements, and environmental exposure. A tailored solution ensures optimal electromagnetic compatibility and regulatory compliance.

What are the benefits of investing in high-quality EMI shielding?

Benefits include protection of human health, reliability and durability of electronic equipment, regulatory compliance, prevention of data loss, and support for sustainability initiatives through the use of recyclable materials.

How can I choose the right EMI shielding provider?

Choose a provider based on industry experience, product range, relevant certifications, customer service, and proven track record. It’s important to request quotes, consult with several companies, and evaluate sample products before making a decision.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services